AI CLOUD INTERCONNECT & HIGH SPEED

The Link That Powers AI, Cloud, and Performance.

At Lisconn, we bring together advanced engineering, precision manufacturing, and complete in house capability to deliver world class solutions for the high speed connectivity industry. Serving markets such as AI, data centers, telecom, HPC, and immersion cooled systems, we provide a one stop shop where innovation meets manufacturing scale.

Speak to a Trusted Lisconn Expert

Fill in your details and we’ll get back to you as soon as possible

Engineering Excellence in High Speed Connectivity

At Lisconn, we bring together advanced engineering, precision manufacturing, and complete in house capability to deliver world class solutions for the high speed connectivity industry. Serving markets such as AI, data centers, telecom, HPC, and immersion cooled systems, we provide a one stop shop where innovation meets manufacturing scale.

Our high speed cable assembly operations include DAC, ACC, and AEC production lines, supported by internal hot bar soldering technology capable of terminating up to 62 pins in a single cycle. Every cable we produce benefits from our 100% in house design and manufacturing process, incorporating HFSS simulation, conductor and plastic material processing, advanced FEP extrusion with skin foam skin technology, and precision taping. This vertical integration allows us to deliver products ranging from 6 Gbps to 224 Gbps in sizes from 25 AWG to 34 AWG, all with exceptional signal integrity.

Our expertise extends beyond cables. We design and manufacture connectors in form factors including OSFP, OSFP RHS, QSFP DD, QSFP, and SFP, as well as internal cables such as MCIO, Riser Card, Mini SAS HD, Gen Z, and OCulink. Leveraging our latest tooling technology – combining precision CNC machining with advanced 3D simulation – we produce injection moulded components that meet the most complex and high performance requirements with consistent quality and minimal waste.

Within our PCB, PCBA, and paddle card production capabilities, we offer CST and Polar simulation, SMT and PTH assembly, BGA placement, die and wire bonding, and COB assembly. Our experience covers both passive and active copper PCBA as well as optical transceiver and AOC builds, enabling us to deliver complete interconnect solutions under one roof.

We are also leaders in immersion cooling interconnect design, manufacture, and validation, following OCP immersion criteria and testing under PAO4, DL, DC, and ICL 1100 liquids. This ensures our products perform reliably in the most demanding thermal environments. Throughout all processes, we apply strict signal integrity engineering – controlling conductor geometry, dielectric consistency, and termination quality – to guarantee minimal loss, low crosstalk, and flawless high speed transmission.

With every stage of production handled internally, from concept through to high volume manufacturing, Lisconn delivers the speed, precision, and innovation needed to power the next generation of global connectivity.

Deliver better products in less time by leveraging an engineering team that speaks your language

Lisconn’s specialized expertise makes it easy to get the solutions you need. Keep your products relevant and your customers excited to purchase.

TRANSCEIVERS

Lisconn’s high-speed optical transceivers are engineered for next-generation data centres, AI clusters, and cloud infrastructure – delivering uncompromising performance from 100G to 800G.

With support for OSFP and QSFP form factors, Lisconn modules feature VCSEL-based transmitters, low power consumption, and reach distances up to 100 metres on OM4 multimode fibre. Each product is hot-pluggable, RoHS compliant, and designed for 0°C to 70°C operating environments, ensuring reliability under demanding workloads.

Compliant with IEEE 802.3, QSFP and OSFP MSA, and CMIS 5.0 standards, these transceivers combine precision optical engineering with robust EMI immunity and low latency. Whether connecting AI servers, top-of-rack switches, or hyperscale interconnects, Lisconn provides consistent, high-bandwidth links that power intelligent infrastructure.

Available Speeds: 100G / 200G / 400G / 800G

Optical Interface: MPO-12 / Dual MPO-12

Wavelength: 850nm VCSEL

Reach: Up to 100m (OM4)

Power Consumption: as low as 2.5W (100G) to 17W (800G)

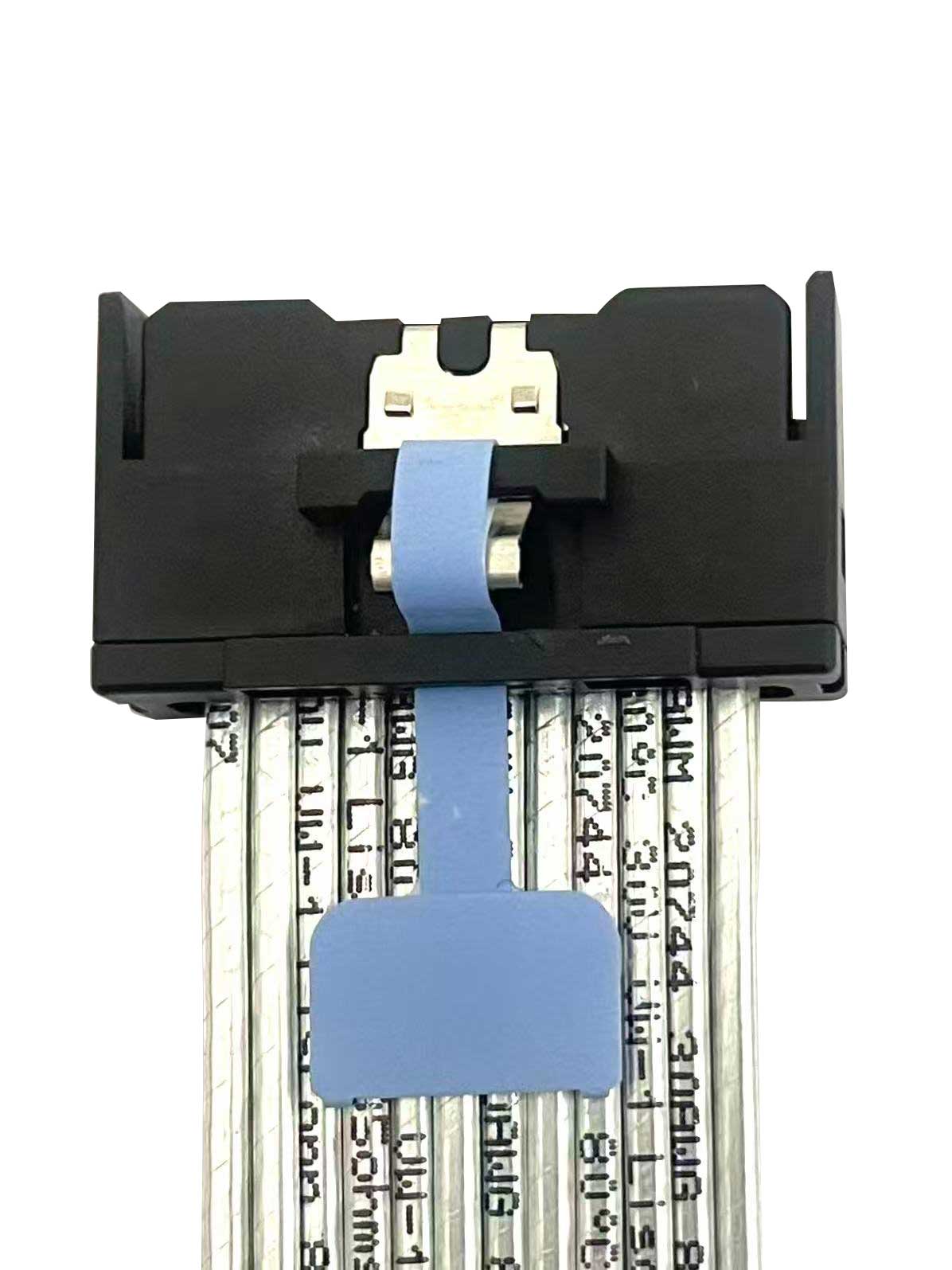

MCIO HIGH-SPEED INTERCONNECT SOLUTIONS

Lisconn’s MCIO (Mini Cool Edge IO) cable and connector systems deliver ultra-high-speed, low-latency signal integrity for next-generation server and accelerator architectures. Supporting PCIe Gen5/Gen6, CXL, and other emerging high-bandwidth protocols, Lisconn MCIO assemblies provide data rates up to 112 Gbps per lane while maintaining exceptional EMI shielding and mechanical reliability.

Available in x4, x8, and x16 configurations, Lisconn MCIO solutions enable compact, flexible board-to-board or board-to-cable designs that reduce power loss and maximise airflow efficiency. Each assembly is engineered for the demanding requirements of AI servers, GPU clusters, and hyperscale data-centre infrastructure.

Key Features:

- Supports PCIe Gen5 / Gen6 and CXL applications

- Data rates up to 112 Gbps / lane

- Compact, high-density footprint for advanced system layouts

- Excellent signal integrity and EMI shielding

- Available as vertical, right-angle, and cable-plug options

- Ideal for AI accelerators, networking, and storage systems

Performance. Precision. Connectivity – at the speed of AI.

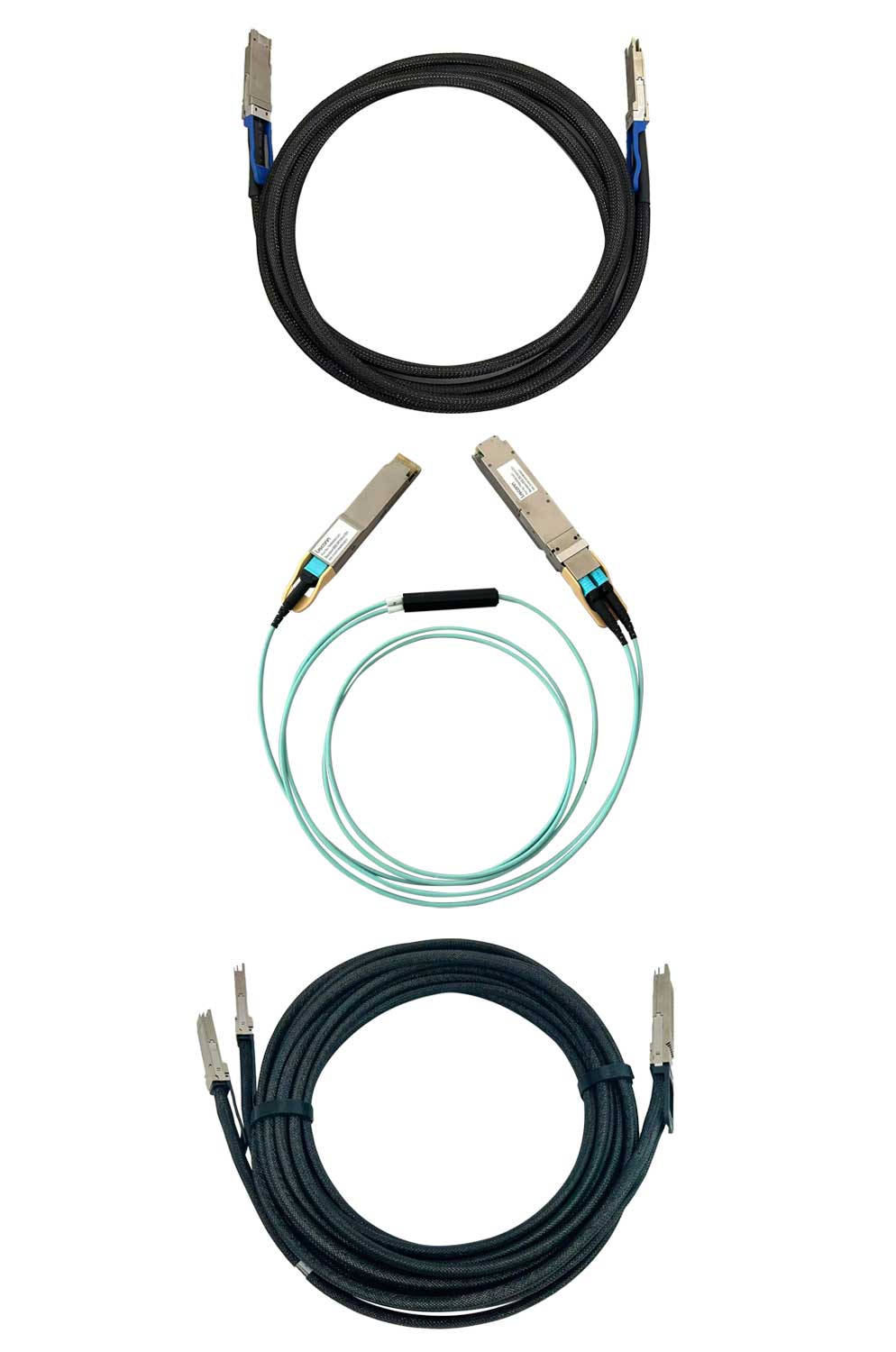

High-Speed Cable Assemblies

As data centres evolve to power the next generation of AI and cloud computing, interconnect speed and reliability define system performance. Lisconn’s high-speed Direct Attach Copper (DAC) and Active Optical Cable (AOC) assemblies deliver uncompromising signal integrity, low latency, and power-efficient data transfer from 100 G to 800 G.

Engineered around QSFP-DD, OSFP, QSFP56, and QSFP28 architectures, Lisconn cables bridge the world’s most demanding environments – from hyperscale GPU clusters and HPC networks to top-of-rack switching and AI accelerator interlinks. Each assembly is precision-built for next-generation PAM4 signalling, maintaining exceptional EMI shielding, thermal stability, and mechanical endurance.

Lisconn offers a full range of configurations to meet diverse system requirements:

- QSFP-DD ↔ QSFP-DD – high-density 800 G copper or active copper connections for switch-to-switch and server-to-switch links.

- OSFP ↔ OSFP – optimal thermal design for dense GPU and AI chassis interconnects.

- QSFP-DD ↔ OSFP – cross-standard interoperability between platforms.

- QSFP-DD ↔ 2 × QSFP56 and QSFP56 ↔ QSFP56 – flexible breakout and aggregation options for 400 G / 200 G fabrics.

- QSFP28 ↔ QSFP28 – proven 100 G performance for existing data-centre systems.

Available in passive and active copper variants, with lengths up to 3 metres, each assembly combines low power, low latency, and high signal fidelity – ensuring smooth data flow between compute, storage, and network layers.

Key Features

- Supports 100 G / 200 G / 400 G / 800 G architectures

- PAM4 signalling with superior signal-integrity design

- QSFP-DD, OSFP, QSFP56, QSFP28 interface options

- Passive and active copper, plus matching AOC solutions

- Excellent EMI shielding and mechanical durability

- Custom lengths and breakout configurations available

Engineered for the Future of Intelligent Connectivity

Lisconn’s high-speed cable assemblies form the backbone of the AI Cloud Interconnect ecosystem – powering the world’s most advanced data-centre and computing networks with precision, performance, and reliability.

Tailored Solutions for Every Stage of Development

At any phase of the product lifecycle, Lisconn provides scalable, high-reliability solutions that drive efficiency, flexibility, and long-term success. Whether you need on-demand services or full turnkey manufacturing, our expertise ensures you get a customized solution designed for performance, reliability, and market competitiveness.

AI Cloud, Interconnect & High Speed

Design, IoT & Engineering

Proprietary Lisconn Components

Interconnect Manufacturing: Cable & Harness

Lean Manufacturing: Electromechanical & PCBA

Systems Integration & Test

Bulk Cable

Fulfillment & Aftermarket

Exceptional quality and reliability when nothing else will do

Your Trusted Partner for Tailored Solutions

Whether you’re developing a groundbreaking new device or optimizing an existing product, Lisconn provides the expertise and resources to bring your vision to life—on time and with precision.

Speak to a Trusted Lisconn Expert

Fill in your details and we’ll get back to you as soon as possible